I swore off turbo-charged cars after the mid 1980s, I’d had enough of the lag until 3500 RPM and then the boost would come on with a rush (though it was fun), the nasty side affects of a turbo-charged FWD car pulling wildly under power when exiting corners, and the all-around amateur feel of the OEM turbo-chargers on affordable cars of that era. And then the siren song of the N54 bit me . . .

Twenty years after my last turbo-charged car, I bought another. This one equipped with BMW’s N54B30 (‘N’ is for ‘New’, 5 = the cylinder count (no, it’s not 5, but because 8 cylinders is represented by BMW as a ’6′, then 6 cylinders has got to be something else, in this case ’5′), ‘B’ = ‘Benzine’, and ’30′ = displacement in deciliters). It also employs direct gasoline injection and two tiny turbo chargers in parallel.

If there’s one knock on this type of turbo setup, it’s that the twin turbos have to be throttled back at higher engine RPMs in order to avoid spinning themselves to death. Those little turbos have to spin much too quickly at higher engine RPM to produce the same boost pressures they did at lower RPM. And that’s why the torque curve on the N54B30 is a tall mesa between 1400 – 5000 RPM, but falls off the face of the earth afterwards.

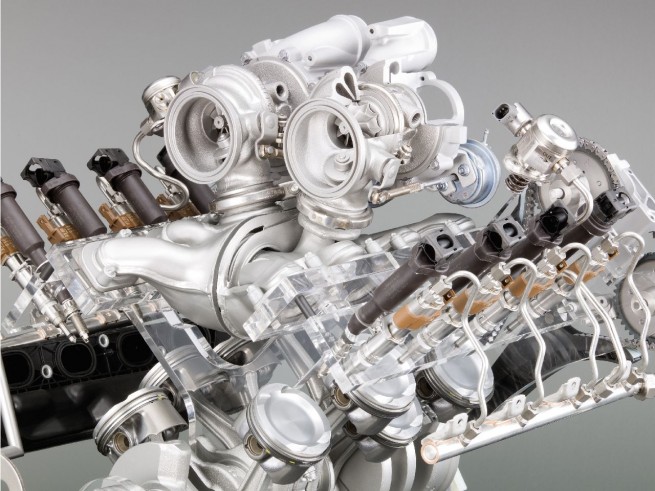

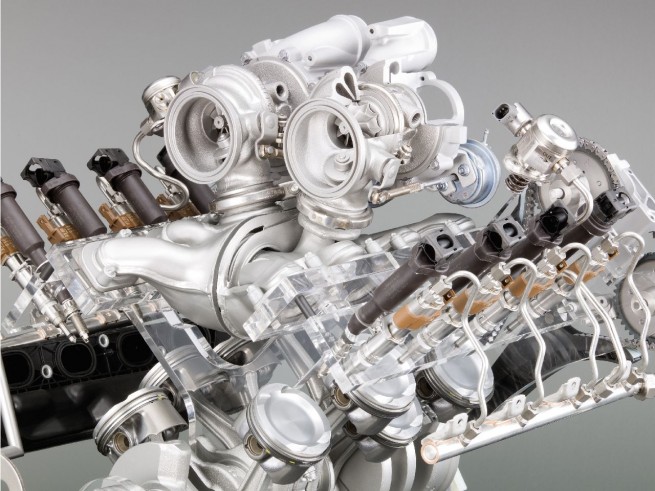

BMW TwinPower Turbo shown here

So, how can that be fixed, we’ll take an approach known as compound supercharging. In this case, utilize the two small turbos for low RPM operation and employ a third turbocharger for higher RPM operation. A BMW tri-turbo engine can be done in a couple of ways.

One is to plumb the turbos to operate sequentially. This will run the smaller turbos up to a specific engine RPM, boost level where a transition to the third turbo will take place and the intake track is

supplied from the output of the bigger, third turbocharger at high RPM. The drawback to this system is the Rube Goldberg plumbing necessary to make it work (and the system tweaking needed to make sure the transition is seamless).

Another way of accomplishing it is through staged turbo-charging. This would use two turbos (or a combination thereof) of similar size to provide a multiplying effect on boost. If the first (set of) turbo(s) produces three times compression of inlet air and the second turbo is fed the output of the first stage, and then boosts that three times further, you’ve effectively squared the boost (the turbos deliver a total of nine times the input pressure). The drawbacks of this setup are lag, and an unresponsiveness to fairly rapid RPM changes. This type of turbo-charging was used in piston engined aircraft.

So of the two types of compound turbo-charging the type that makes the most sense for an N54 derivative would be the sequentially engaged turbo-chargers, if they can package the plumbing needed to do it in the existing space.

Now if they just made the next M3 FWD, they’d be able to cram the plumbing for the sequential turbos in the nose with no problem . . .JUST KIDDING!!!!

Twenty years after my last turbo-charged car, I bought another. This one equipped with BMW’s N54B30 (‘N’ is for ‘New’, 5 = the cylinder count (no, it’s not 5, but because 8 cylinders is represented by BMW as a ’6′, then 6 cylinders has got to be something else, in this case ’5′), ‘B’ = ‘Benzine’, and ’30′ = displacement in deciliters). It also employs direct gasoline injection and two tiny turbo chargers in parallel.

If there’s one knock on this type of turbo setup, it’s that the twin turbos have to be throttled back at higher engine RPMs in order to avoid spinning themselves to death. Those little turbos have to spin much too quickly at higher engine RPM to produce the same boost pressures they did at lower RPM. And that’s why the torque curve on the N54B30 is a tall mesa between 1400 – 5000 RPM, but falls off the face of the earth afterwards.

BMW TwinPower Turbo shown here

So, how can that be fixed, we’ll take an approach known as compound supercharging. In this case, utilize the two small turbos for low RPM operation and employ a third turbocharger for higher RPM operation. A BMW tri-turbo engine can be done in a couple of ways.

One is to plumb the turbos to operate sequentially. This will run the smaller turbos up to a specific engine RPM, boost level where a transition to the third turbo will take place and the intake track is

supplied from the output of the bigger, third turbocharger at high RPM. The drawback to this system is the Rube Goldberg plumbing necessary to make it work (and the system tweaking needed to make sure the transition is seamless).

Another way of accomplishing it is through staged turbo-charging. This would use two turbos (or a combination thereof) of similar size to provide a multiplying effect on boost. If the first (set of) turbo(s) produces three times compression of inlet air and the second turbo is fed the output of the first stage, and then boosts that three times further, you’ve effectively squared the boost (the turbos deliver a total of nine times the input pressure). The drawbacks of this setup are lag, and an unresponsiveness to fairly rapid RPM changes. This type of turbo-charging was used in piston engined aircraft.

So of the two types of compound turbo-charging the type that makes the most sense for an N54 derivative would be the sequentially engaged turbo-chargers, if they can package the plumbing needed to do it in the existing space.

Now if they just made the next M3 FWD, they’d be able to cram the plumbing for the sequential turbos in the nose with no problem . . .JUST KIDDING!!!!

No comments:

Post a Comment